Packaging 101: What is Bleed, Trim, and the Safety Zone?

We have the pleasure of working with many customers on custom packaging. We do not handle print or creative design in-house, but we do collaborate with printing and packaging partners who do so on behalf of our customers. To ensure that your end product is exactly how you envision it, having design files with a proper bleed and the right formatting is very important in the custom packaging process. Bleeds, trim, and safe zones are tools that manufacturers and printers use to accommodate small variances in the production process. Despite the advanced nature of most modern equipment, there is a margin of variability when cutting printed media to size and shape. Understanding these concepts will help your design team handle these types of projects.

What is Paper Bleed Used For?

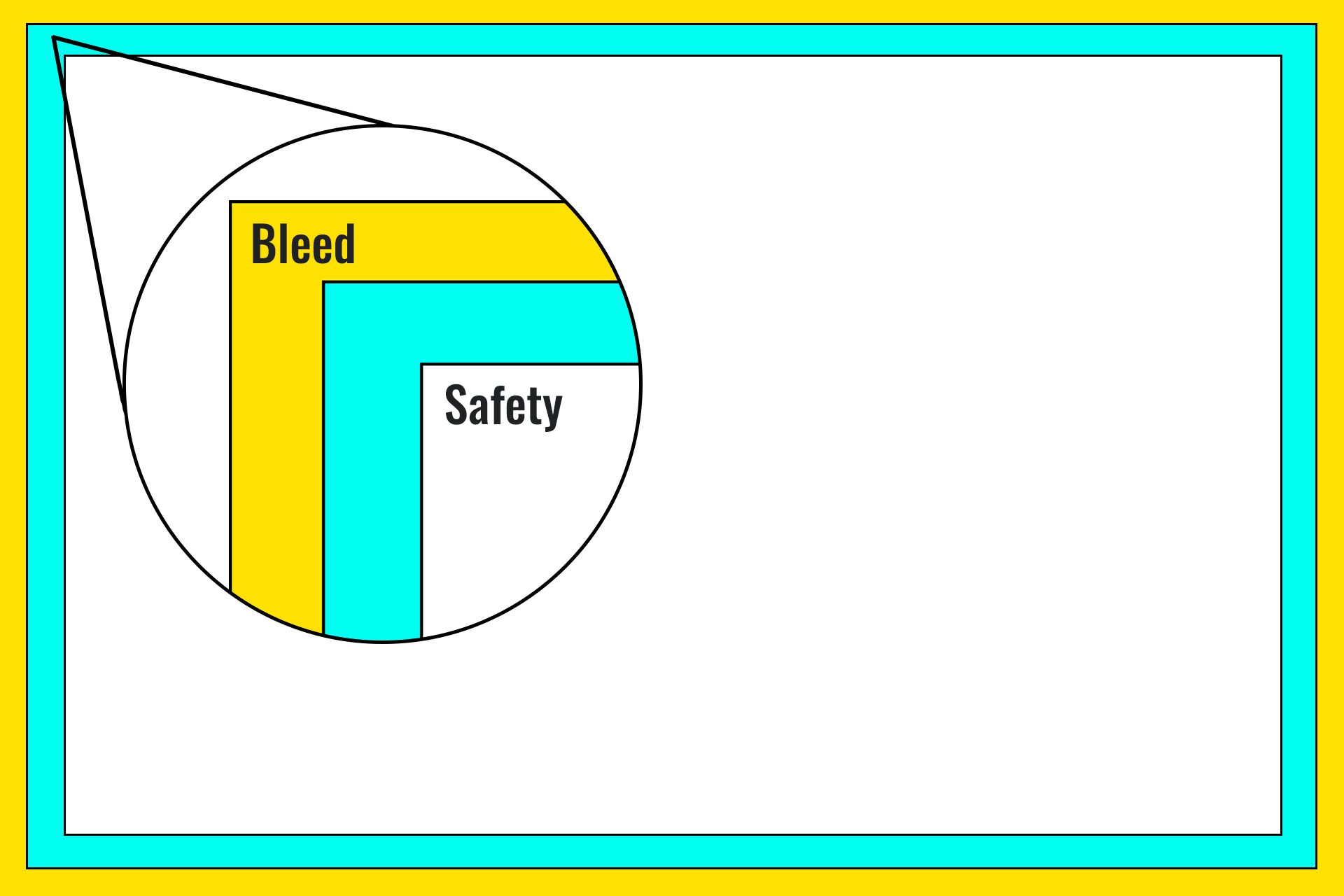

The term “bleed” refers to a design being printed so that the image and/or color “bleeds” to the edge of the substrate. In the print and design world, bleeds are very important. Without bleeds, your print project may have thin white borders visible around the outer edge of the sheet and ensures that your design goes edge to edge. For example, when you print a picture at home there is a thin white border around the image even though on your computer it goes all the way to the edge. This is because there is no bleed set.

When you add bleeds to your print document, the image and/or color will go beyond the edge of the paper, giving you an area to cut from. The standard bleed measurement is 0.125 inches, but this may vary depending on what your manufacturer requires.

What is a Paper Trim Line?

The trim line refers to the final size and shape of the project after it has been printed and cut out.

What is the Safety Zone?

Paper safety is the inner margin area on a design that is guaranteed not to get cut off or distorted during the cutting process. Elements to keep within the safety zone should include:

- Logos

- Important text

- Page numbers

- Heading and footing text

- Important images and graphics

The Importance of Custom Packaging

The Importance of Custom Packaging

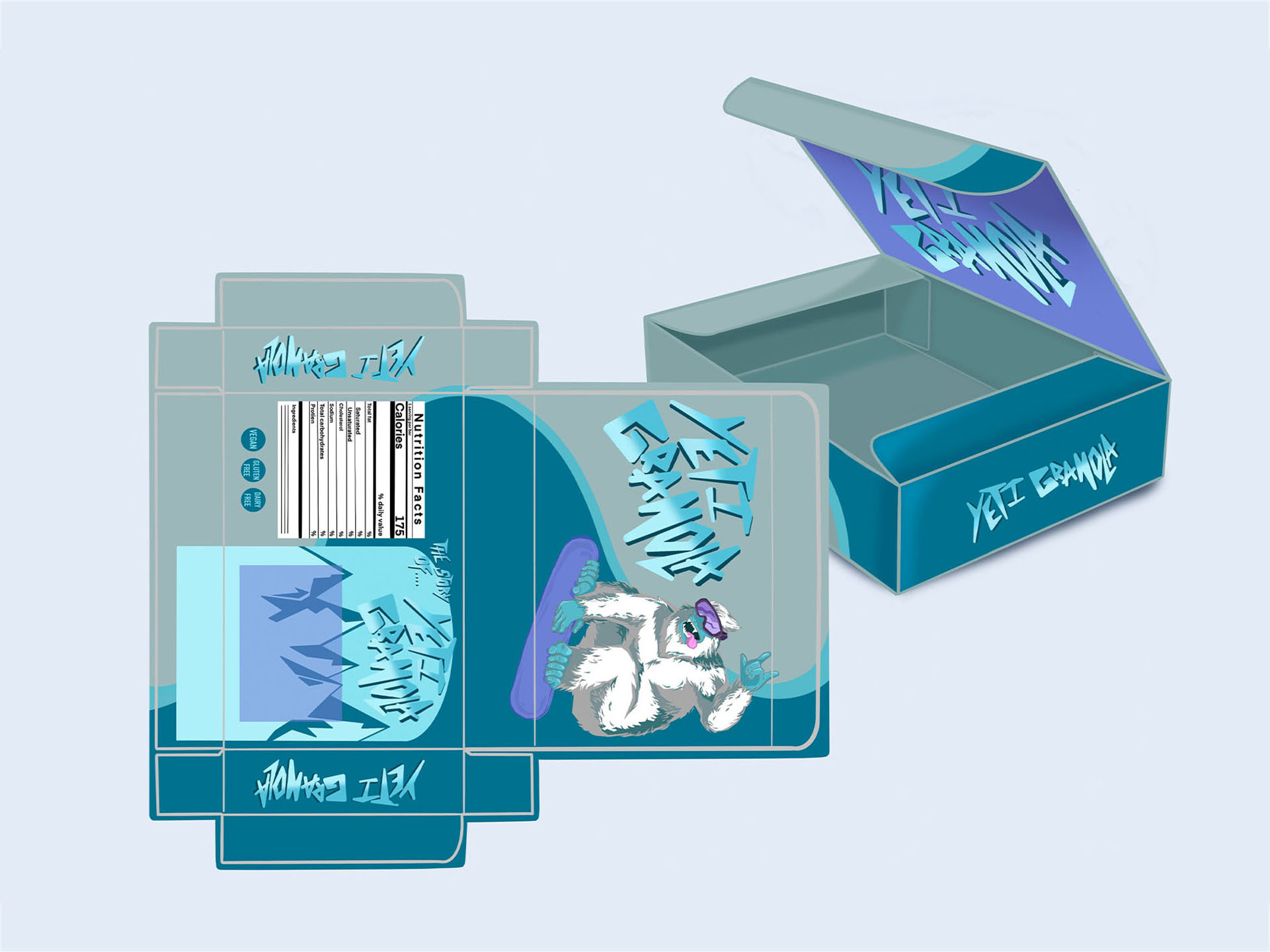

Did you know that 70% of consumers say that packaging design influences their purchasing decisions? Thoughtful designs can make your product look more attractive and professional in the eyes of consumers. Custom printed packaging can help make your products stand out against competitors, enhance the consumer unboxing experience, and be used as an extension of your brand’s identity. You can customize your packaging with your brand colors and logos, images, or a personalized message.

To achieve the exact look you are going for, make sure your design file is set with proper bleeds to print edge to edge and all important information is within the safety zone. Not doing so may result in text and images being cut off when the packaging is constructed or them not lining up properly along the edges.

Learn more

Learn more

Let us help you during your next custom packaging project. For more information, contact your local WCP team. We’d be happy to set up a consultation to discuss the best packaging options to meet the goals of your next upcoming project and business. Give us a call today at (877) 398-3030.