How to Determine the Right Flute – Packaging 101

How to Choose the Right Flute for Corrugated Packaging

Did you know that approximately 80% of the packaging in the United States and the European Union are packed in corrugated packaging? With so many products being shipped in corrugated packaging, such as boxes and mailers, it is important to know how to choose the right flute. So to help distinguish what type of corrugated flute is right for what purposes, we have broken down what each type is good for. Keep in mind though, that the thickness in flute material does not replace the need for other packaging cushioning such as paper, packing peanuts, and bubble wrap to keep your packages safe.

What is Flute?

If you were to cut a piece of cardboard in half, the flute is the wavy material sandwiched in between two walls of paperboard. Fluting is important because it is what reinforces or stiffens the corrugated material so that it is less likely to be crushed or collapse. As you can imagine this is especially important for shipping and transporting products and goods.

What are the Types of Flute?

- A-Flute is 1/4 inch thick corrugated material. It is best used for cushioning fragile products.

- B-Flute is a 1/8 inch thick corrugated material. It is a flatter and smoother surface, so it is best used for high quality printing and die cutting.

- C-Flute is a 3/16 inch thick corrugated material. This flute size is what is commonly used for packaging.

- E-Flute is a 1/16 inch thick corrugated material that is used as an alternative for paperboard folding cartons.

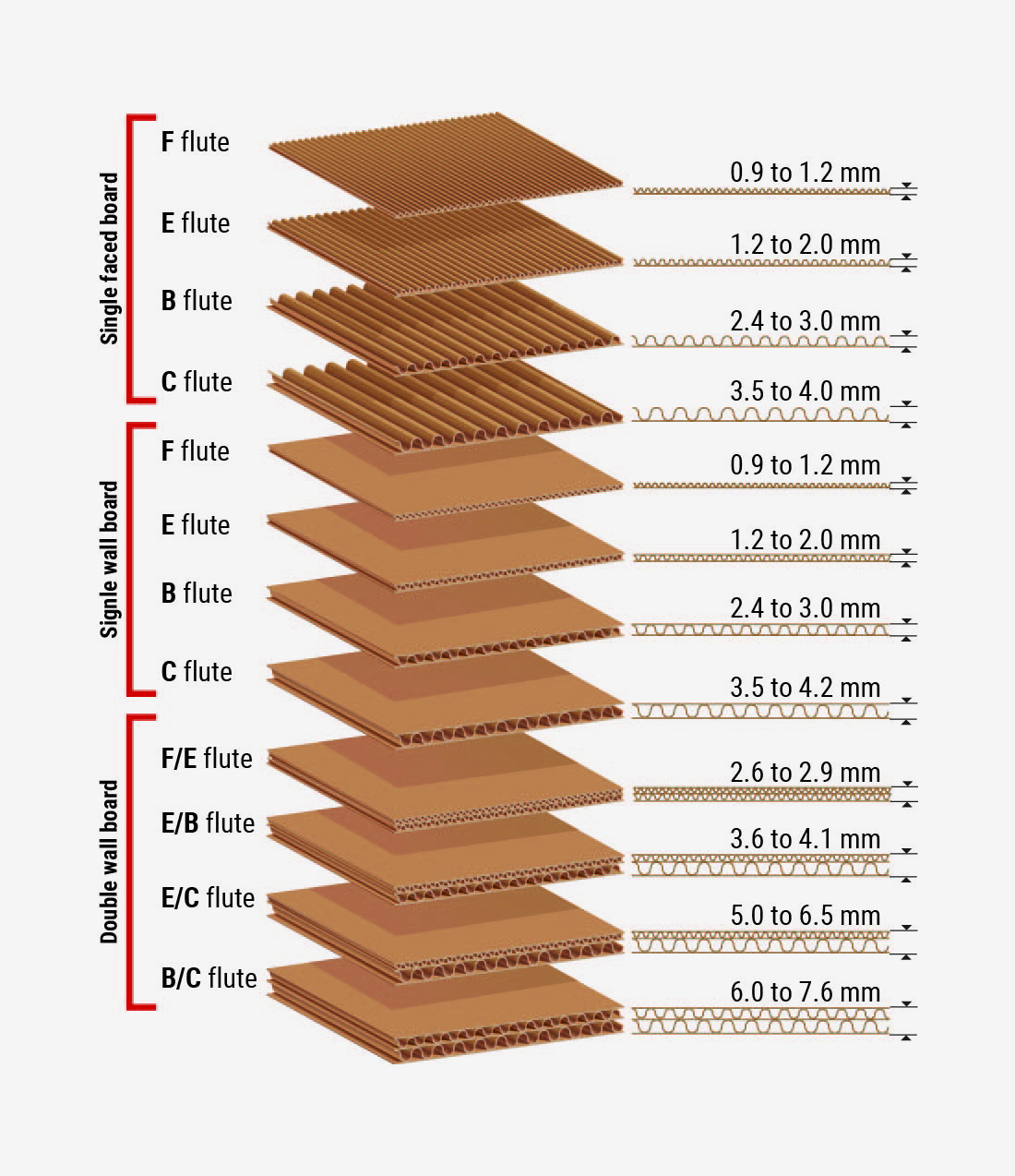

Flute Thickness and Construction

The type of flute thickness is not the only thing to consider for your packaging material. You should also keep in mind how many walls your flute has. As shown in the below image showing the three different flute wall classifications and their thicknesses.

Another factor to keep in mind for companies trying to improve on efficiency and reduce freight costs is that the smaller flutes have the potential to fit more on a pallet and it will weigh less. As well, it can take up less room on a truck and in a warehouse.

Benefits of Choosing Custom Packaging

Thinking about going custom with your packaging? We have solutions for that too! We can even help you design a prototype to assure it fits the needs of your product and business. Click here to learn more about the benefits of choosing custom packaging.

Learn More

For more packaging information and to answer any of your questions, contact your local WCP account manager or customer service team. Want to see what items are readily available in our stock box program, click here to view our Stock Box Guide. We’d be happy to set up a consultation to discuss packaging and custom shipping boxes to meet the goals of your business. Give us a call today at (877) 398-3030.

Source: Cardboard Baler