The Different Adhesive Types for Labels and Stickers

When choosing a label or sticker, understanding the distinction between ultra-removable, removable, and permanent adhesives is an often misunderstood but incredibly important factor in selecting the best product for your application. Whether you require a temporary solution, a semi-permanent hold, or a strong bond, knowing which adhesive type to choose ensures that your projects are successful. In this post, we will explain each adhesive type, explore their common applications, and other variables to consider when choosing a pressure sensitive label.

What are the Three Types of Adhesives?

1. Ultra-Removable: Ultra-removable adhesives are designed to be removed easily. Depending on the substrate (surfaces), once applied, they can be taken down or moved easily without damaging surfaces. However, it may lose its “stickiness” if it gets moved around too much or becomes dirty. Note: Ultra-removable labels will fall off when applied to many substrates.

An example of this type of adhesive would be retail advertisements at convenience stores on their refrigerator coolers. They are applied and taken off weekly with new promotions. They go on easily and can be removed cleanly from the glass.

Ultra-Removable Applications can include:

- Temporary retail promotion – window graphics

- Temporary policy changes

- Temporary warning signs on smooth surfaces

2. Removable: Removable adhesives are designed to remove cleanly from surfaces and be repositioned after the initial installation. Over time they can become permanent. Note: Removable labels can fall off when applied to difficult substrates like plastic, corrugated boxes and mailers, or textured surfaces such as a wall.

An example of removable adhesives would be a shelf talker label found in retail stores. They are low-cost paper labels that are applied and removed regularly as the price or product placement changes.

Removable applications can include:

- Business hour signage

- Temporary signage

- Price tags

- Children’s stickers

3. Permanent: Permanent labels are designed to remain in place and not be removed. Once applied, they can not be repositioned or moved. If attempted to move, it will leave paper and adhesive residue on a surface. Permanent adhesive is the most common adhesive used with labels, and according to our partners, they account for approximately 85% of labels.

Permanent applications can include:

- Product labels

- Packaging and shipping labels

- Name badges

- Outdoor signage

- Industrial applications

Looking for Label Paper? Try Before You Buy!

What you are sticking your label to is just as important as the adhesive you choose to use. Some surfaces and substrates are difficult to stick to, while others are very easy. Generally, smooth surfaces such as glass and fine paper are very easy to stick to. Difficult surfaces include plastic, corrugated cartons, and textured walls. The general rule is to test the product before you buy.

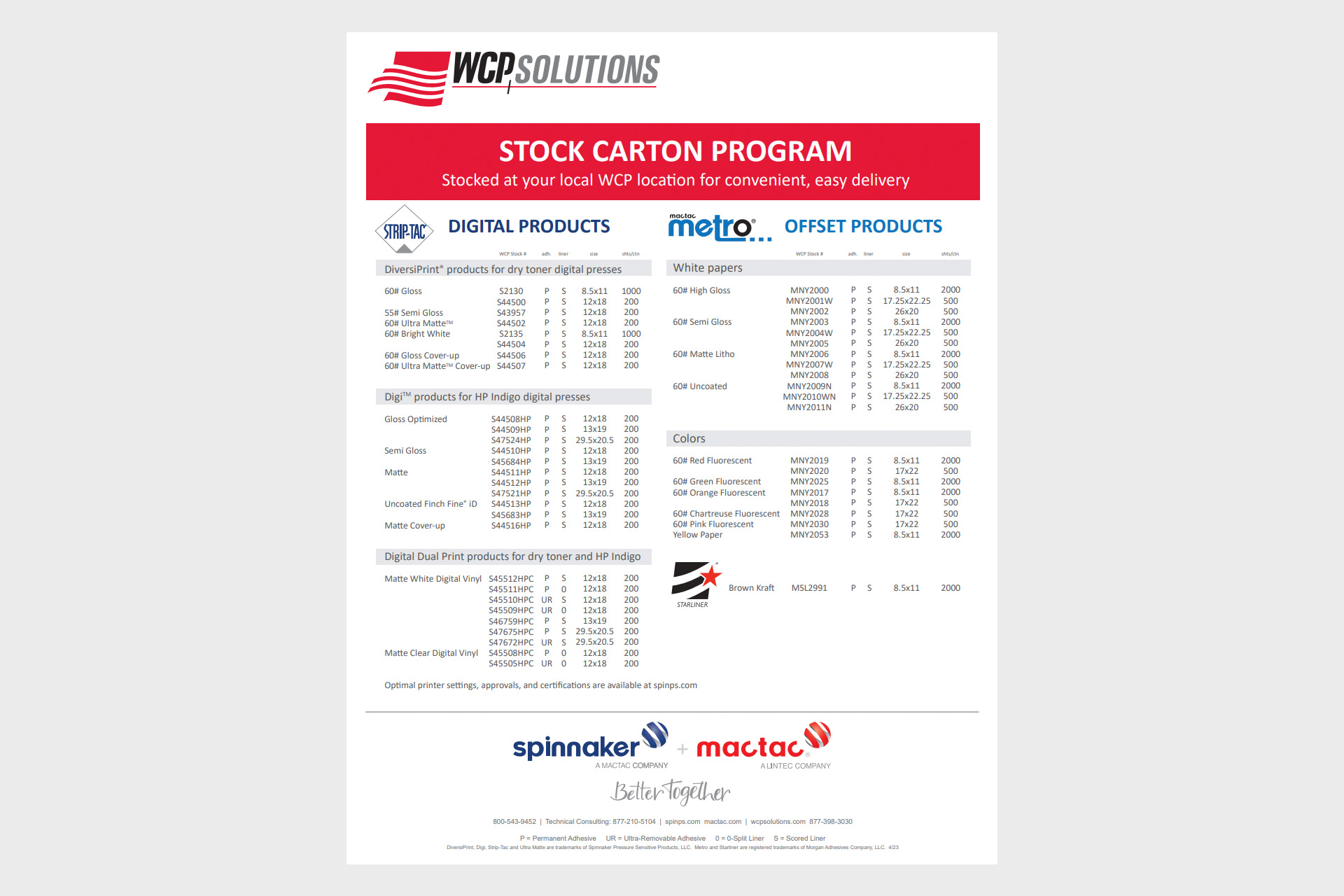

We recently relaunched a Pressure Sensitive program with one of our partners Mactac/Spinnaker. To learn more about the program and see our current stocking items click here.

Let us help you find the perfect label paper for your business. Our industry experts have the knowledge to help you choose the right paper face stock, adhesive, and finish for your application. For more information, contact your local WCP account manager or customer service team and check out other resources like our paper calculator. Give us a call today at (877) 398-3030.