Stretch Film – Packaging 101

Things to Keep in Mind When Choosing a Stretch Film

If you are involved in moving, loading, or manufacturing products, you know how important it is to choose the right stretch film. Stretch film helps to keep packages safe when they get jolted or handled roughly during shipping. If you use the wrong stretch film, you might have to wrap a pallet multiple times to protect it from getting holes, known as puncture points. This could lead to your items getting damaged during transit or using more material than necessary, causing you to spend more money than needed.

What is Stretch Film?

Stretch film is a transparent, strong, stretchable film material used to wrap products and/or boxes on a pallet. The material tightly holds the items together and helps reduce movement during transportation.

What Stretch Film Should You Use? And for What Purpose?

Below are some gauge guidelines for standard non-high-performance stretch films.

- 37 Gauge Films: Better suited for lighter, uniformed objects and for loads less than 800 lbs.

- 47 Gauge Films: Better suited for heavier, uniformed objects that do not have sharp edges or corners and for loads less than 1800 lbs.

- 80 Gauge Films: This is the most common gauge of stretch film. Due to its versatility, it can be used in a variety of applications for loads between 2,200-2,400 lbs.

- 100 Gauge Films: Commonly used for bundling larger boxes together and for loads between 2,800-3,000 lbs.

For high-performance stretch film, consult your WCP Account Manager and Manufacturer. Our team would be happy to do a cut and weigh to analyze the cost per pallet wrapped. Choosing a high-performance stretch film will allow you to use a lower gauge, known as down gauging, which has the added benefit of using less material, saving you wrap time and money.

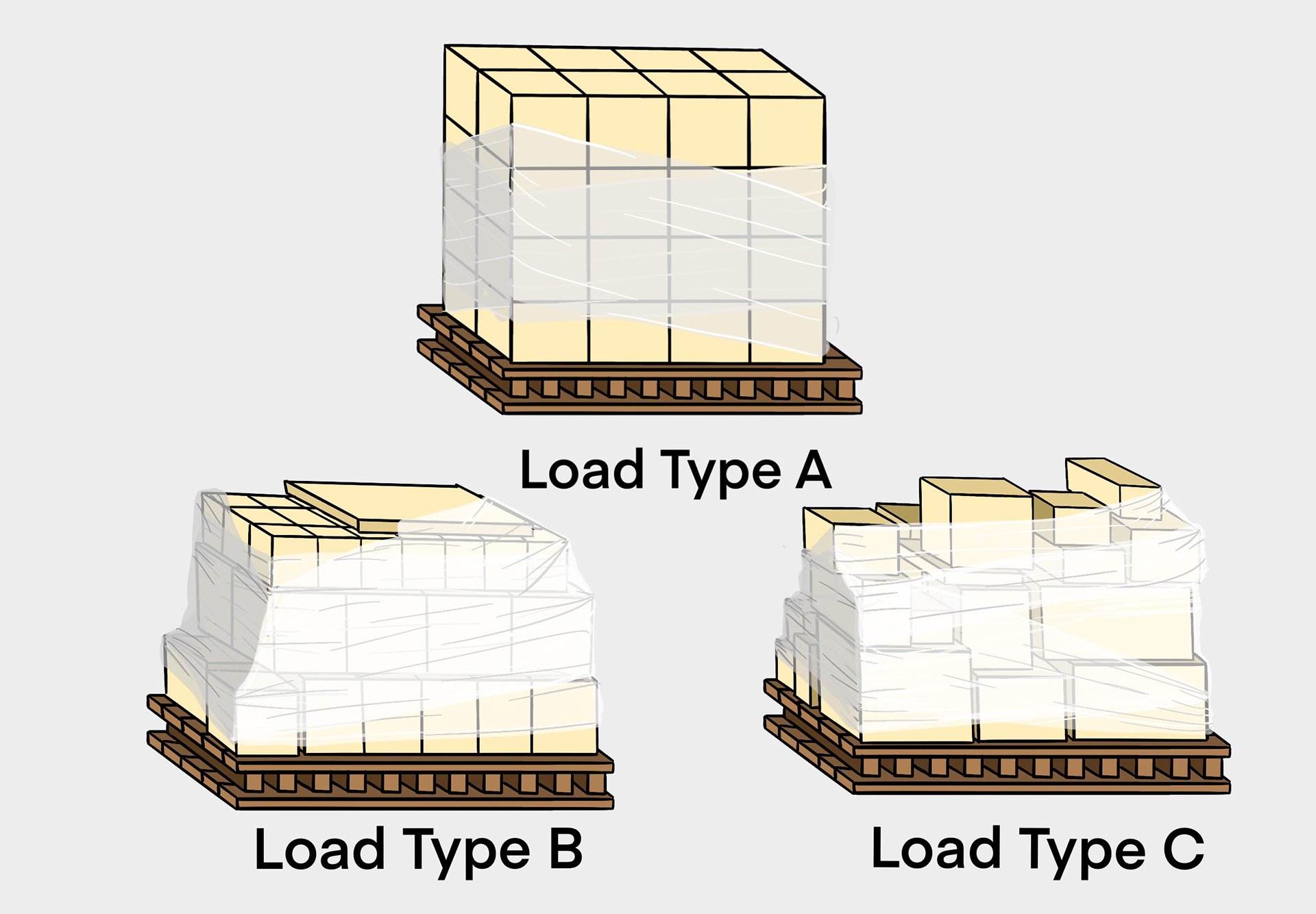

The 3 Load Type Categories When Using Stretch Film

- Load A-Types: Pallet loads that fall under “Load A-Types” are uniform in shape and almost match the size of the pallet. Because everything on the pallet is close in size, this load is the easiest to wrap and there are minimal puncture points to cause tearing in the film. Load A-Types are common in manufacturing where multiple units of the same products are being shipped out.

- Load B-Types: Pallets with “Load B-Types” have an irregular stacking pattern and/or the product may not match the pallet size. Due to the irregularity of the stacking, multiple puncturing points exist (keep in mind that more stretch film may be required when wrapping due to the numerous puncture points). You can typically find Load B-Type pallets at smaller manufacturing organizations and distribution centers where items on a pallet are different.

- Load C-Types: A Load C-Type is when each pallet is loaded differently, creating ranges in load sizes, shapes, and puncture points. Like load B-Type pallets, load C-Types may require more film wrapping to strengthen the durability of the puncture points and minimize shifting.

Things to Keep in Mind When Choosing a Stretch Film Gauge

- The distance the items on the pallet need to travel; the further you travel, the great risk of product damage.

- The weight of the pallet with the products: the heavier the product, the more durable the stretch film you will need.

- The load type, size, and the number of puncture points present on your pallet.

- How irregular each pallet load will be from one to the next; if each pallet is going to be different, you will want a more durable stretch film to cover a wide variety of loads.

Automated Stretch Wrappers and Packaging Equipment

Make the packaging process easier with automated machinery. Click here to see different types of pallet wrapping machines and other packaging or janitorial equipment that our team can offer. Or visit our Equipment Resource page to contact our equipment specialists and see our featured vendors.

Learn More

For more information on stretch film, contact your local WCP account manager or customer service team. We’d be happy to set up a consultation to discuss products, set up a cut and weigh, or look at custom packaging solutions for your business. Give us a call today at (877) 398-3030.

Source: Paragon Films and US Packaging and Wrapping