How to Choose the Right Can Liner Type and Gauge?

Selecting the right can liner is more than just grabbing the nearest trash bag. There are two types of can liners, low-density and high-density. Each is designed for specific waste needs, and using the wrong one can lead to unnecessary waste or mess. In this post, we’ll explain the key differences between these two liners, highlight their best uses, provide a quick conversion guide for mils to microns, and break down how can liners are measured to help you make informed decisions.

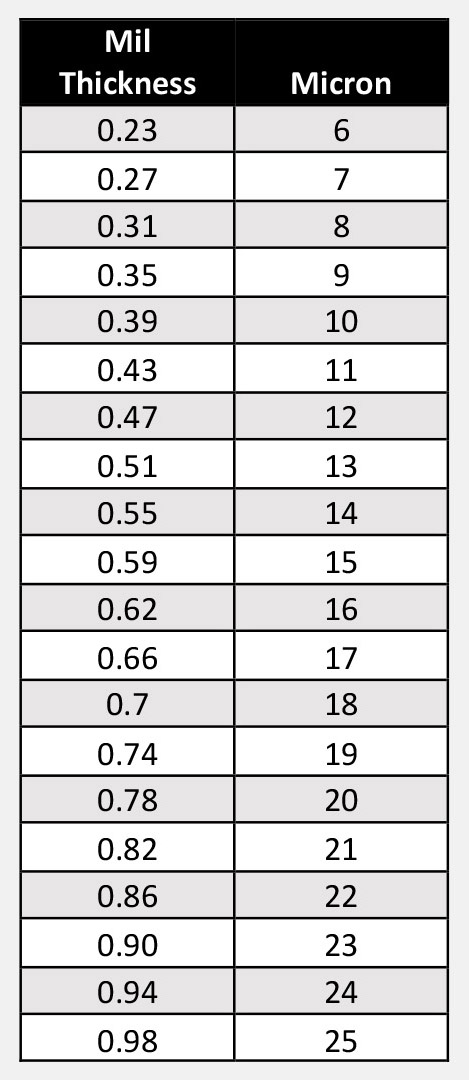

Measuring Can Liners in Mils and Microns (Conversion Chart)

Gauge is a measurement of thickness in can liners. Can liners are measured in mils or microns. Knowing how to convert between the two measurements can help ensure you select the right thickness for your needs. However, the bigger the number, regardless of whether the measurement is in mills or microns, the thicker and more durable the can liner will be.

- Mil: A mil is a unit of thickness that is equal to one-thousandth of an inch (0.001 inch). It is commonly used to measure the thickness of low-density can liners. Low-density can liners typically range from 0.30 to 6.0 mils, and you can convert a mil to a micron by multiplying by 25.4.

- Micron: A micron is one-millionth of a meter and is commonly used for measuring high-density liners. High-density can liners can range from 6 to 24 microns. To convert a micron to a mil, divide by 25.4.

Note: One mil is equal to 25.4 microns, and one micron is equal to 0.039 mils.

Characteristics and Usage of Low-Density Can Liners

Low-density can liners are designed for heavy-duty tasks. Though they have a lower gauge than high-density liners, it does not mean they are of lesser quality or less durable. In fact, low-density liners are thicker and more flexible. This makes them ideal for handling sharp, heavy, or irregularly shaped objects that could potentially puncture or tear thinner liners.

When to use low-density liners:

- When there will be sharp or jagged items like glass, metal, or wood being tossed

- When there will be heavy-duty trash, such as construction debris or food waste

- In environments where flexibility and stretchability are needed

In light, dry waste environments, 0.35 to 0.50 mil liners are sufficient. However, for environments like restaurants, healthcare, or construction sites, thicker liners from 1.0 mil to 3.0+ mil provide the strength needed to handle sharp or heavy materials.

Characteristics and Usage High-Density Can Liners

High-density can liners are made from thinner, stronger plastic, making them a cost-effective option for disposing of lighter and less rigid waste. These liners use less plastic overall, making them more environmentally and cost-friendly when weight is a concern. While high-density liners may not offer the same puncture resistance as low-density liners, they excel in environments where durability is less of an issue.

Some common applications for high-density liners:

- 6-12 microns: These liners are the thinnest and commonly used for light-duty trash, small offices, and restrooms, where the likelihood of sharp objects being tossed into them is low.

- 12-17 microns: This gauge is suitable for medium-duty trash in cafeterias or kitchens with mixed waste, such as food waste and take-out containers.

- 17-25 microns: Thicker high-density can liners are for extra-heavy-duty trash, such as in areas with bulky items, such as manufacturing facilities, warehouses, and outdoor public spaces like parks or stadiums.

Featured Can Liner Suggestions

Here at WCP, our Supplyways can liners range from different sizes, colors, and gauges to fit your business’ needs. Below are just some of the liners we have for different trash bins.

- 24×24 6MIC High-Density Supplyways Can Liner – This liner is suitable for 7-gallon trash bins that are common in office facilities or school classrooms.

- 33×39 1MIL Low-Density Supplyways Can Liner – This liner is for 30 to 33-gallon trash bins that can be used in outdoor public spaces like parks.

Learn More

Our Account Managers can help you find the right can liner for you and your business, whether you are disposing of sharp, heavy materials or lightweight office waste, there is a perfect liner for your needs. Contact your local WCP account manager or customer service team to learn more.